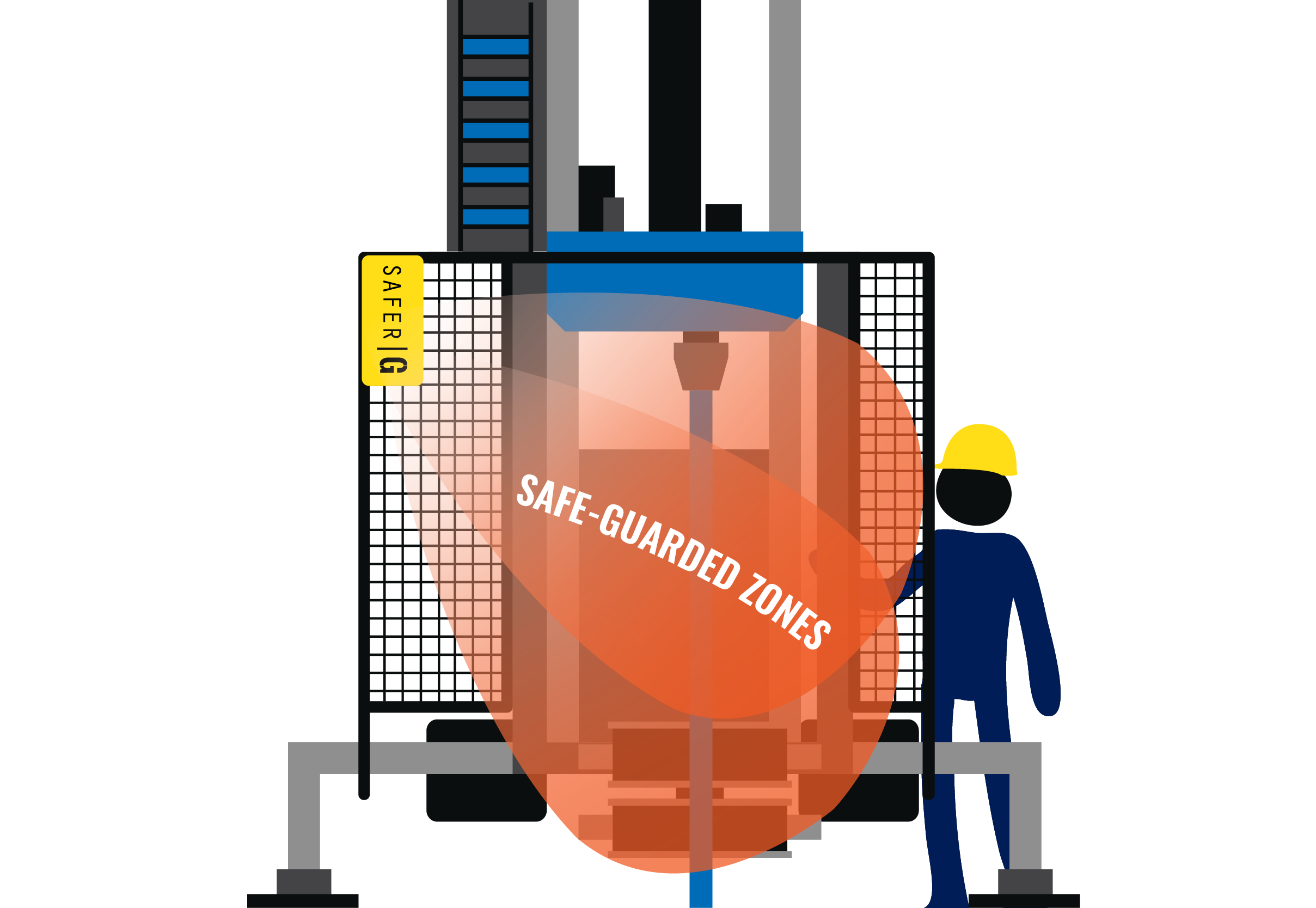

When your rotary rig is stopped, waiting on a malfunctioning physical guard to be fixed, you’re losing metres, time and margin. SAFER G resolves that by replacing clunky physical guards with sensor-activated intelligence that detects human entry, while ignoring dust, cuttings and flush. You get continuous drilling, fewer interruptions, demonstrable compliance and a safer site that delivers results - not just reports.

Everyone on site knows the physical guard on a rotary drilling rig is a pain in the arse. Open it, close it, wait. Every time someone changes a rod, adds casing or removes a sample barrel, it’s another dance between the drill crew and the steel. It slows down the job, frustrates everyone on site, and often gets bypassed when people are in a rush.

Built in the UK, CE‑marked and award‑winning, it’s the only guard designed from the ground‑up for rig crews who want fewer injuries, less downtime, and every minute drilling counts.

We will only ever contact you via email. The information you provide here will not be used by any other party, nor will it be used to distribute our marketing via any other medium. For full information regarding how we handle your data in compliance with the GDPR, please see our Privacy Policy.